Touch Screen Integration

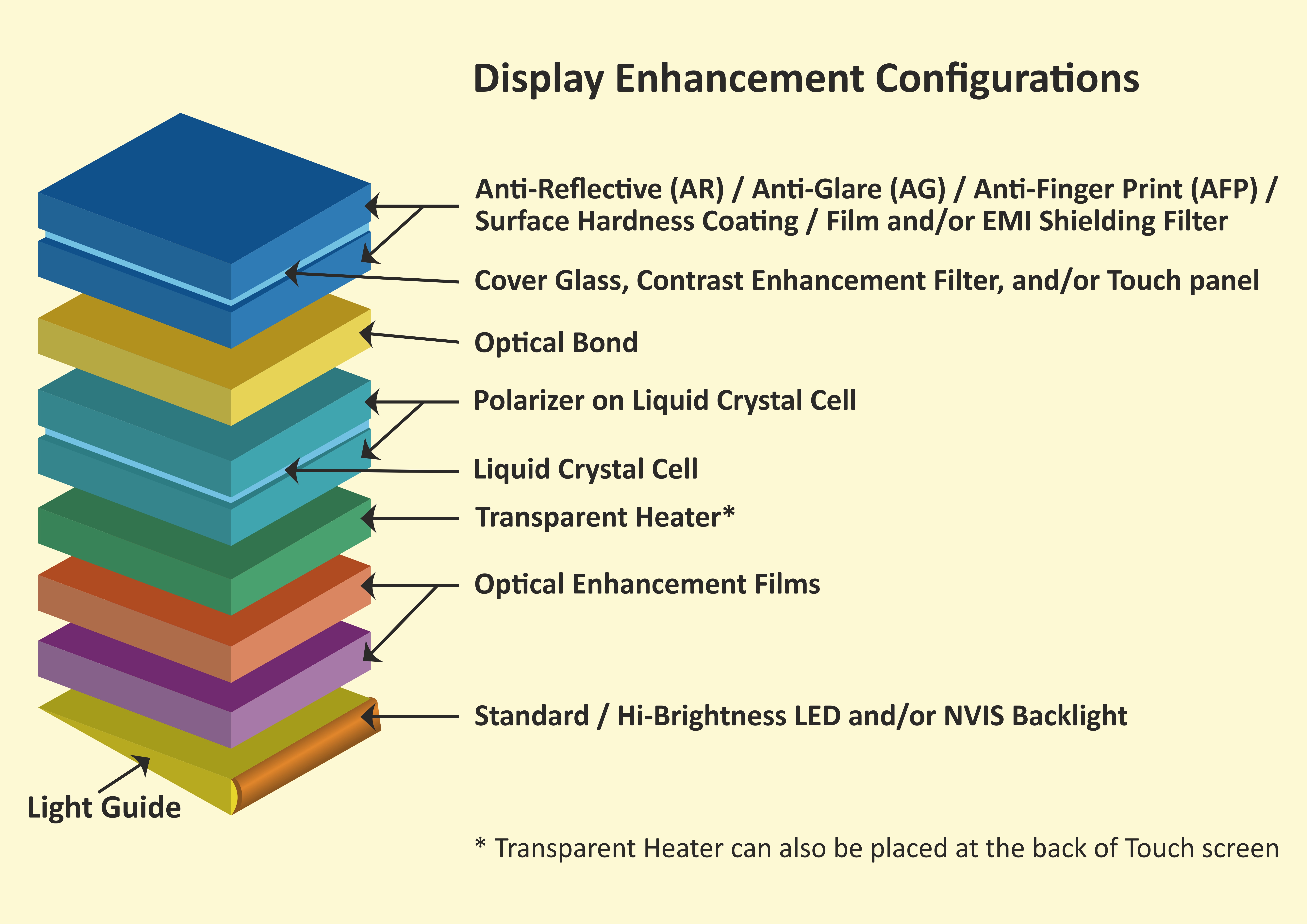

#HighnessMicro has cleanroom and in-house bonding facility to integrate Single or Multi-point Touch Screen of various types into almost all display sizes to make it interactive. Our featured touch screen offerings include- Vandal Proof; Anti-Glare, Anti-Reflective & Anti-Finger Print coating; Chemically Toughened (Up to 7H Hardness) and Touch Screens integrated with EMI-Mesh for shielding. These touch screens can be tape or optically bonded on display surface. Customized touch screens with very thin substrate or increased thickness are also available for integration with displays.

Display Controllers

Our in-house engineering team have excellent expertise to offer Display Controllers with a variety of input and output interfaces that can be tuned with almost any TFT-LCD module. These controllers provide easy driving circuitry and in-built color calibration software to enhance displays’ imaging capabilities.

Open-Cell Bonding

#HighnessMicro has cleanroom and in-house bonding facility coupled with experienced engineers who can offer open-cell bonding services wherein open-cell glass can be integrated together with a standard or customized backlight unit. Our strict and more-so standardized QC technique ensures all displays are bonded to perfection and that the brightness of backlight is uniformly distributed.

Tape Bonding

Our Tape-Bonding procedure is undertaken in cleanroom environment unlike various other similar service providers. This not only ensures dust and other unwanted particles are kept away but also proper alignment. An Industrial or Ruggedized grade double-sided adhesive tape is used on the bezel of the display to bond glass-substrate or touch screen on the surface. Although this leaves a gap in between two layers that is not suitable for outdoor usage or usage under direct sunlight, but it is the most cost-effective method of bonding. In case of indoor applications, this is the most preferred option as compared to its counterpart Optical-Bonding.

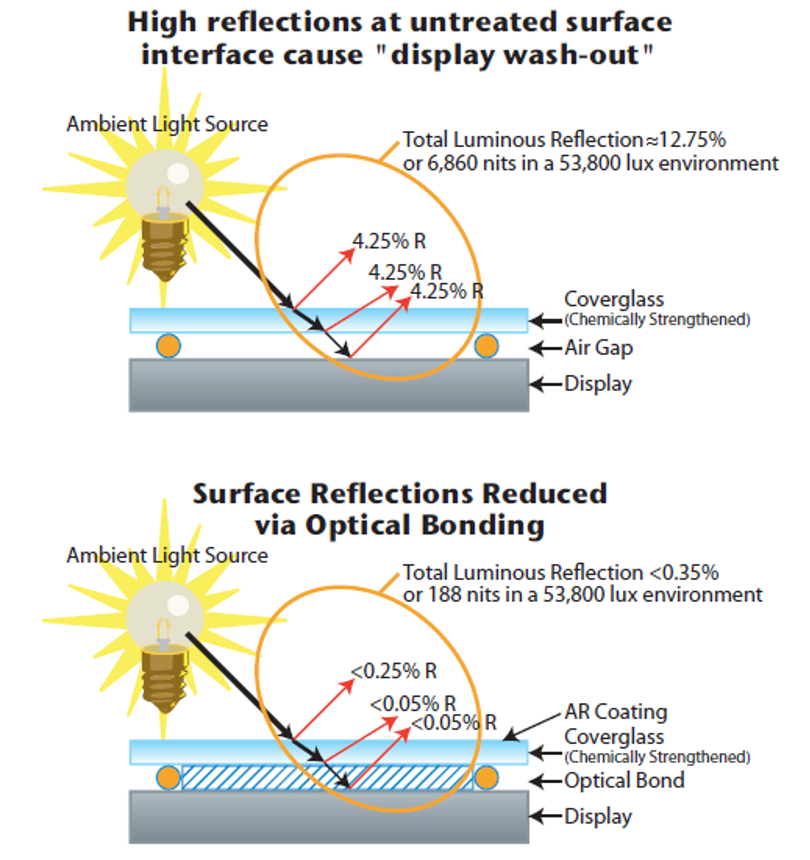

Optical Bonding

Unlike Tape-Bonding, Optical-Bonding is done to ensure better visibility in outdoor conditions and under direct sunlight as well as achieve better ruggedization of the display product. In order to fill-up the gap between top surface layer that could be glass-substrate or touch screen and display surface, A UV adhesive liquid that is even laid out that fills the gap between two layers thereby reducing light reflection as shown In the image below. An optically-bonded display is best for outdoor visibility under direct sunlight as well as it make the entire display product extremely rugged for use with high vibration and shock.

Brightness Enhancement for Outdoor and Ambient Sunlight

#HighnessMicro has expertise to design and integrate high-brightness backlights to the existing display module in order to make it a truly high-bright display product. Depending on the display size, our backlight enhancements may differ. Our modified backlight modules are power-saving so as to make it possible to use the display product on auxiliary power is needed. We also offer backlight driving circuit along with this, which has built-in PWM or manual brightness dimming controls.

EMI/EMC/RFI Shielding

Our EMI-Mesh for shielding has qualified various standards such as MIL-STD-461E and MIL-STD-461F. This shielding mesh provide extensive & efficient attenuation against Electro-Magnetic Interference. We, at Highness have expertise to integrate these EMI-Mesh to display products. We can integrate this shielding mesh on a glass-substrate or a touch screen and further tape or optically bond it on display product surface.

Optical Enhancement Surfacing

In order to enhancement optical characteristics of a display, we provide coating services such as Anti-Glare, Anti-Reflective and/or Anti-Fingerprint (Smudge-proof). The top surface can be treated with these coating to achieve desired results as the application may be.

Surface Hardness/Toughening

For ruggedized display product, we offer toughening services by adding a hard-coat film or a chemically toughened Glass-Substrate. This addition helps to achieve the display product surface to reach up to 7H hardness level.

Operating Temperature Widening

#HighnessMicro can expertise to add transparent thermal heaters or heating coils to increase the operating temperature of display product. The optically-transparent heater can be added in the display stack and the coils can be placed at the rear of the display product. By adding these, it is possible to achieve operating temperature level of up to -50o C.

Night vision compatibility

#HighnessMicro has expertise to modify existing backlight of a display product to make it night-vision compatible. With ultra-low dimming controls, these display products qualify for well for NVIS tests. In most display products, it is also possible to have dual backlights which helps in making the display product dual mode and it can function on Day and Night mode on the same hardware.

Enclosure Assembly

We have excellent mechanical engineering capabilities and we offer our services in display product enclosure assembly. We specialise in enclosure assembly for critical applications with thermal concerns or thin-design requirements. Our mechanical engineering capabilities also include designing and integration of display products that are required to withstand high vibration and shock in application such as Railways, other similar transport industry, Mining etc.

Cable & Wire Harness

With in-house production capabilities such as semi-automation and fully automatic machines, #HighnessMicro can design and offer cables and wire harness for various application. Complicated cable designs, shielding / coaxial wire harnesses, Mil-grade circular connectors etc are our forte.